Challenge: Growth of the mushroom industry in Ontario is limited by labour shortages, recruitment barriers, and labour-intensive harvesting Solution: Develop a systems level modelling tool that allows growers to gauge economies and effectiveness of automation tools implemented for harvesting processes across different mushroom varieties Impact: The new process technology can be implemented across multiple farms as a service-based model to help growers make informed decisions about automation in their specific operation and lower the risk of automation investments

In Canada, more than 90 per cent of mushroom production and harvesting occurs year-round in Ontario and British Columbia, with over 100 farms nationwide. However, the industry is currently facing labour shortage issues that are leading to farms losing revenue and limiting their growth.

Harvesting is the hardest role to fill, as it’s labour intensive, and can lead to work-related musculoskeletal disorders. Due to this, the mushroom industry is looking to investments in harvesting automation technology.

When simulating any type of system or process, the visualization replaces real-world behaviour and performance to test, gain insights / data, and optimize a process without real-world consequences. Simulation modelling is a tool that can be applied to many agricultural domains to improve harvesting. In this project with Agriculture at UWindsor (AgUWin) and industry partner Sinopa Energy Inc. (Sinopa), the simulation focused specifically on mushrooms. The most popular variety, the white button, is the focus of this research.

Sinopa is a vertically integrated sustainable energy and technology company with a vision to contribute to the establishment of a sustainable future for the planet. They employ innovative smart technologies, sustainable energy sources, energy efficiency, and waste reduction as primary strategies to realize this vision. The company adopts a long-term strategic approach to decision-making, considering the economic, environmental, and social implications with a strong emphasis on sustainability.

Ron Collins, president, and CEO of Sinopa, provides insights into the mindset of farmers, highlighting their cautiousness and the need to understand their unique ways of working. He compares farmers to automotive companies in terms of guarding their methods and being hesitant to change. Ron emphasizes the importance of gathering extensive data to provide well-informed suggestions when working with farmers, as their practices and stated outcomes may differ. This perspective underscores the significance of understanding and respecting the intricacies of the agricultural industry when introducing new ideas or technologies. Ron had worked on other projects with university. He and the university team identified an opportunity for them to work together on this robotic and automation project.

The project was launched after Ron tapped into his network at the Ontario Ministry of Agriculture, Food and Rural Affairs to link up with a regional mushroom farm that expressed interest in automation. With these key players in place, the project commenced.

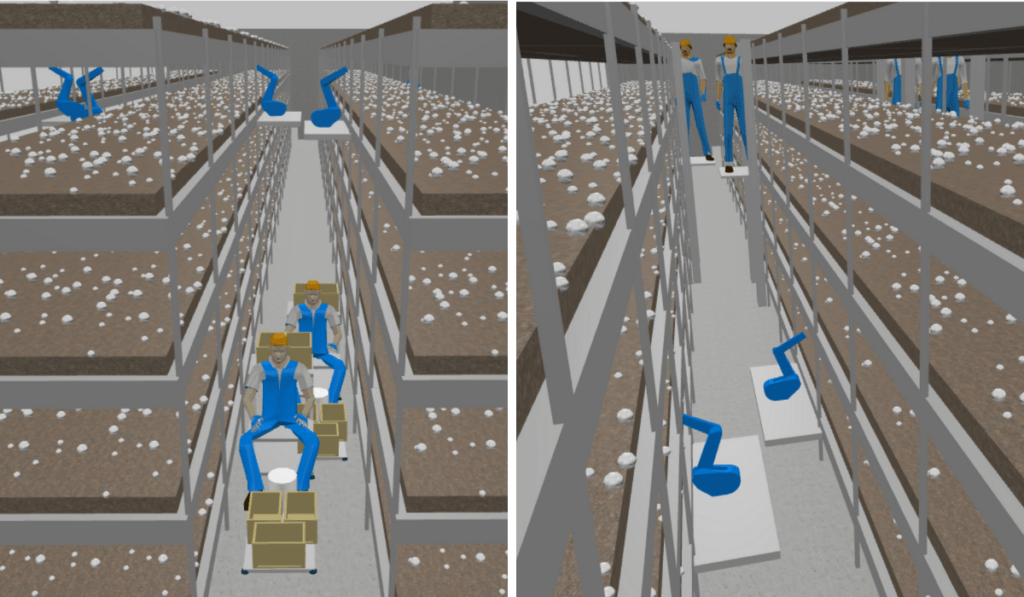

The key objective was to develop the model to simulate the current state in the mushroom farm, investigate a potential future fully automated state, and collaborative scenarios.

The research team at AgUWin also performed sensitivity analyses to develop a roadmap to guide future harvesting simulation developments for other crop types.

The roadmap framework was adapted from Define, Measure, Analyze, Improve, Control (DMAIC) based methodology. The first four phases focused on the simulation modelling and use, while the control phase is a future project at this point.

It was important for the researchers, including Ava Recchia, MASc Industrial Engineering Student at AgUWin, to sift through what they were hearing from farmers and staff, what the data was showing, and come to conclusions based on scientific approaches. They also realized that debriefing the farmer and staff after every site visit provided an opportunity for relationship building and trust.

“The model simulates the harvesting system for a singular production room. To make that model, the current harvesting process was thoroughly documented and measured, including production output data for each mushroom classification type and size,” said Ava.

To calibrate the harvest simulations, the real-world data was analyzed and integrated with the model. Once calibrated, the model could be used to perform ‘what-if’ scenarios. For example, they looked at a scenario where automation harvests only from the lowest two levels and from the upper three, or an option to stagger the start of harvesting.

Ava and the team recorded harvesting activities at each level of the shelving units. For the proposed automation solution, they developed a classification operation to get estimates for picking mushrooms from different regions of the growth area.

“Without the funding provided by the Greenhouse Technology Network, Sinopa would not have been able to conduct such comprehensive research.”

Ron Collins,

president, CEO of Sinopa

Overall, creating simulation models such as the one AgUWin’s team did with Sinopa, will allow Canada’s ag industries to explore the future of automation, which will have impact at all levels of the economy.

Globally, research like this will ensure Canada can continue to be an international leader in mushroom production and exportation.

Regionally across Windsor-Essex/Chatham Kent, there’s an opportunity for growth, as there are approximately 20 per cent of the total Agaricus (various forms include button, brown or large portobello mushrooms) growing mushroom farms in Ontario.

Finally, at the academic level, having the DMAIC framework in place will facilitate future harvesting simulations for mushrooms and other crop types.

“The university demonstrated a high level of professionalism throughout this project. They substantiated to the mushroom farmers that every decision they made was science and data-based, which greatly engaged the staff and facilitated very positive communication,” said Ron.

In terms of feasibility of conducting a project like this one, Ron stressed, “Without the funding provided by the Greenhouse Technology Network, Sinopa would not have been able to conduct such comprehensive research.”

This project was made possible by funding from the Federal Economic Development Agency for Southern Ontario, through the Niagara College-led Greenhouse Technology Network.

Visit Agriculture at UWindsor’s website to learn more about its resources and capabilities.

(Project #UW202)