Challenge: Improve the production and availability of fresh fodder for livestock Solution: Develop indoor controlled environment fodder production technologies and practices Impact: High-quality fodder production year-round with lower water, nutrient and land use

Scientists and industries are rethinking fodder production. An option for this livestock feed supplement is sprouted seeds of alfalfa or barley. When grown for less than a week they can be used as a partial substitute for hay and grains. It offers livestock fresh, green, nutrient-packed sprouted grains. The goal of this project was to boost fresh fodder production while limiting both resources (especially water) and land use.

Endless expanses of mono-cropped corn or soybean grown for livestock feed are no longer sustainable or achievable in resource-constrained regions such as the deserts of the Middle East. An alternate approach would be to grow fodder indoors with controlled environment production systems.

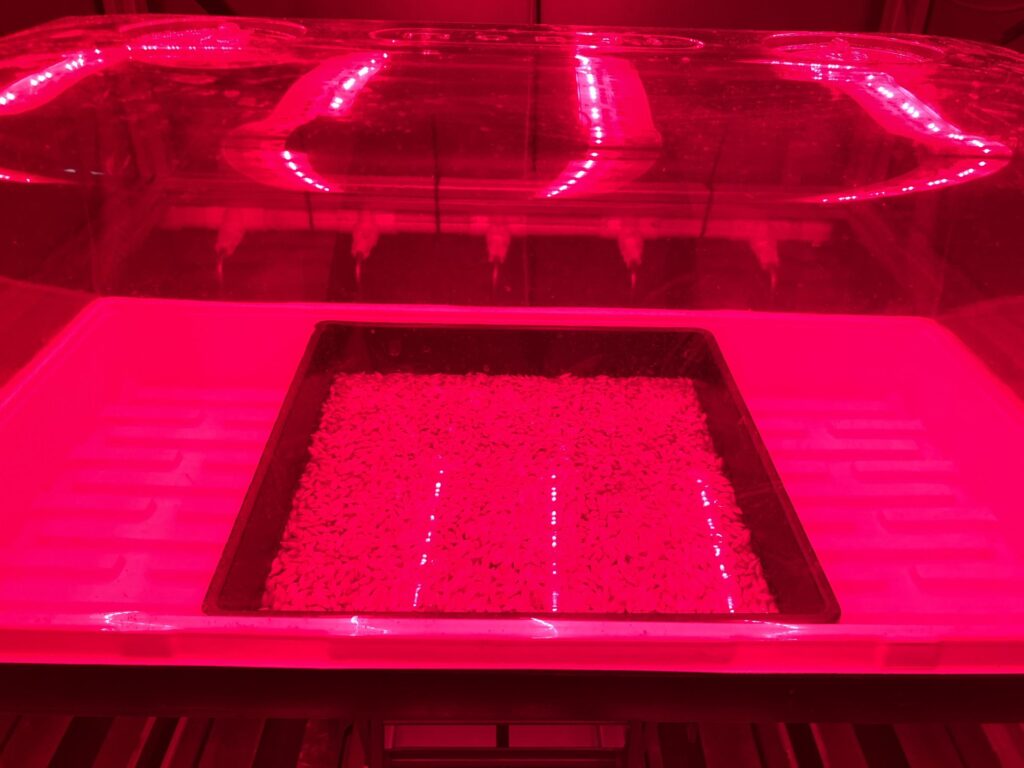

Controlled environment hydroponic production technologies are gaining traction and it has become clear that this technology offers several benefits over conventional farming. For one, controlled environment systems offer a consistent, high-yield fodder source that can be produced 365 days a year. This approach to fodder production can substantially improve yield using only a fraction of water and fertilizers compared to conventional land-based farms.

“We have been refining and advancing the technologies for controlled environment agriculture in collaboration with the CESRF for over a decade and this fodder production project represents the culmination of years of investigation”

~ Josh Siteman, Intravision Light Systems

Intravision Light Systems, a leading provider of high-fidelity controlled environment and LED lighting systems, partnered with University of Guelph’s Controlled Environment Systems Research Facility (CESRF) to develop new knowledge and methodologies to optimize the production of fodder crops in controlled environments.

“We have been refining and advancing the technologies for controlled environment agriculture in collaboration with the CESRF for over a decade and this fodder production project represents the culmination of years of investigation” says Josh Siteman of Intravision Light Systems.

Supported by funding from the industry partner and the Greenhouse Technology Network (GTN), the research team utilized CESRF’s cutting-edge facilities and Intravision’s extensive experience in large-scale hydroponic production to investigate how different growing conditions affect the yield, quality and nutritive value of barley and alfalfa fodder crops.

The environment ‘recipes’ and management practices allowed for optimized plant growth conditions, which aren’t possible on the farm. These results will help producers grow higher-quality fodder crops that meet their livestock’s needs with fewer inputs, ultimately leading to more sustainable and efficient fodder production.

Production technologies, like the one tested throughout this project, will also enable resource-constrained regions, such as the Middle East, to establish a thriving local dairy and livestock industry while reducing their reliance on fodder imports.

While there still are some technical challenges, the results of this project have the potential to significantly improve the productivity of controlled environment fodder production.

This project was funded by the Government of Canada through the Federal Economic Development Agency for Southern Ontario.

Visit University of Guelph’s Controlled Environment Systems Research Facility (CESRF) page to learn more about its resources and capabilities.